- Language

Industrial Ethernet Network Patch Cord

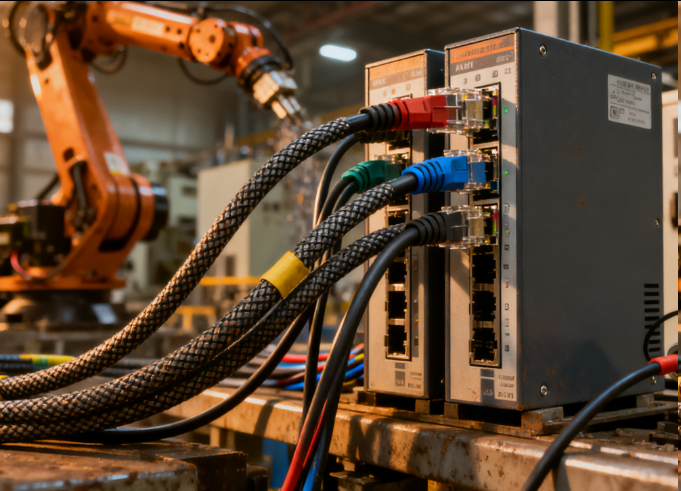

Industrial Ethernet network patch cords are engineered to withstand harsh environments, including extreme temperatures, vibration, and exposure to chemicals or moisture. These cables are commonly used in manufacturing plants, oil refineries, and transportation systems, where traditional networking components would fail. Constructed with ruggedized jackets made of materials like polyurethane (PUR) or thermoplastic elastomer (TPE), they resist abrasion, UV radiation, and mechanical stress.

The conductors in industrial Ethernet patch cords are often stranded copper for flexibility, allowing them to bend without breaking. Many models feature shielded twisted pairs (STP) or foiled twisted pairs (FTP) to minimize EMI and crosstalk in electrically noisy environments. The connectors, typically M12 or industrial RJ45 plugs, are sealed to prevent ingress of dust or liquids, meeting IP67 or IP68 ratings for water and dust resistance.

When deploying industrial Ethernet patch cords, it’s crucial to select cables rated for the specific environmental conditions. For example, cables used in outdoor applications may require additional UV protection, while those in explosive environments must comply with ATEX or IECEx standards. Proper cable routing and secure fastening also prevent damage from machinery or foot traffic, ensuring long-term reliability in industrial settings.

Read recommendations:

LEG 77000 French Type Mosaic Energy Saving Switch 1 Way Switch 10AX (1 module) White

RSH Graffiti Zigbee Bluetooth Mesh Three in One Multimode Gateway

-

Network Patch Cord Cat8

Oct 23, 202592

-

Network Rack Wall Mount with Glass Door

Jan 07, 202679

-

Network Rack Wall Mount 9U

Jan 06, 202675

-

Network Cable Management Tray

Oct 30, 202573

-

Network Cable Management Under Desk

Dec 25, 202572