- Language

Industrial-Grade Network Patch Cord

Industrial-grade network patch cords are specialized cabling solutions designed to withstand the harsh conditions of industrial environments—including extreme temperatures, moisture, dust, vibration, chemical exposure, and physical impact. Unlike standard office or data center cables, which are built for controlled environments, industrial-grade cords are engineered to maintain reliable connectivity in settings such as manufacturing plants, oil refineries, mining operations, power stations, and transportation hubs (e.g., railways, airports), where network downtime can lead to costly production delays or safety risks.

One of the defining features of industrial-grade network patch cords is their rugged construction. The outer jacket is typically made from robust materials such as TPE (Thermoplastic Elastomer), PUR (Polyurethane), or LSZH (Low Smoke Zero Halogen) with enhanced thickness and flexibility. TPE and PUR jackets offer excellent resistance to oil, grease, chemicals, and abrasion, making them ideal for manufacturing or automotive facilities where exposure to lubricants or solvents is common. They also remain flexible in extreme temperatures, with operating ranges from -40°C to 85°C (or higher for specialized models), ensuring performance in cold storage facilities or high-temperature industrial ovens. Additionally, the jacket is often reinforced with a braided shield (made from tinned copper or stainless steel) to protect against physical damage from impact or crushing, a common risk in busy industrial settings.

Shielding is another critical component of industrial-grade patch cords, given the high levels of electromagnetic interference (EMI) from industrial machinery, motors, and power lines. Most industrial cords use STP (Shielded Twisted Pair) or SFTP (Screened Foil Twisted Pair) shielding, which combines a foil layer around the conductor pairs and a braided outer shield to block EMI and reduce crosstalk. Some models also include a drain wire for proper grounding, further enhancing interference protection. This ensures that data transmission remains stable and error-free, even in environments with intense electrical noise—critical for industrial automation systems, which rely on real-time data to control machinery and processes.

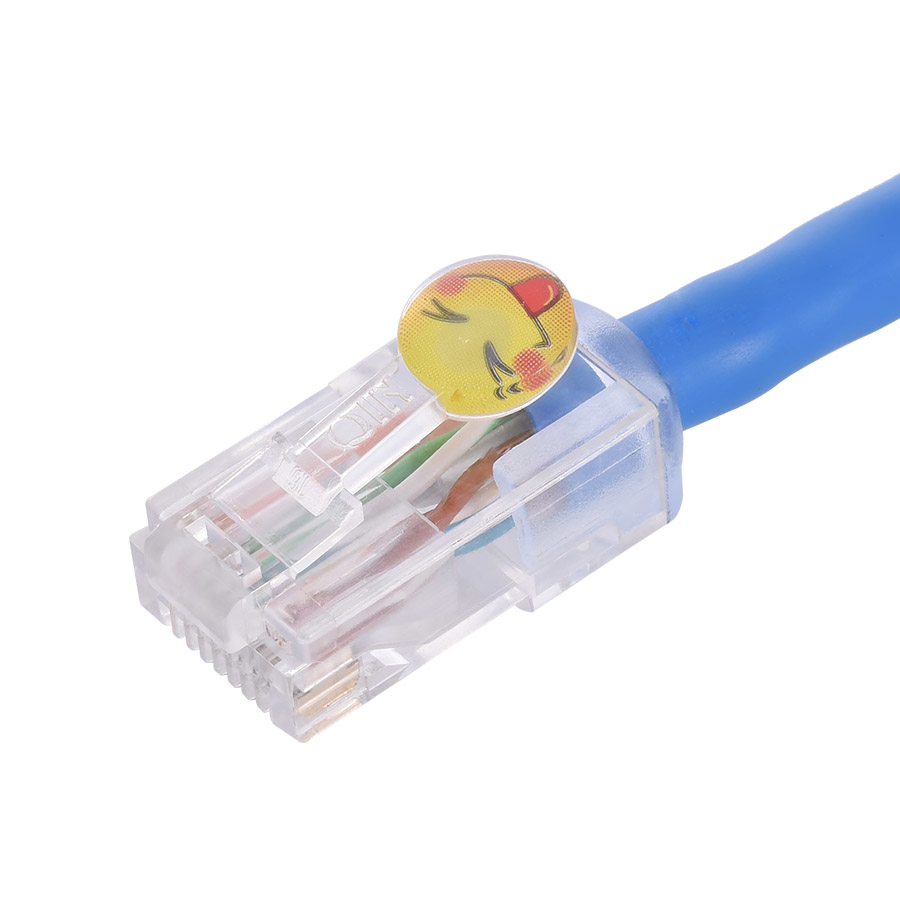

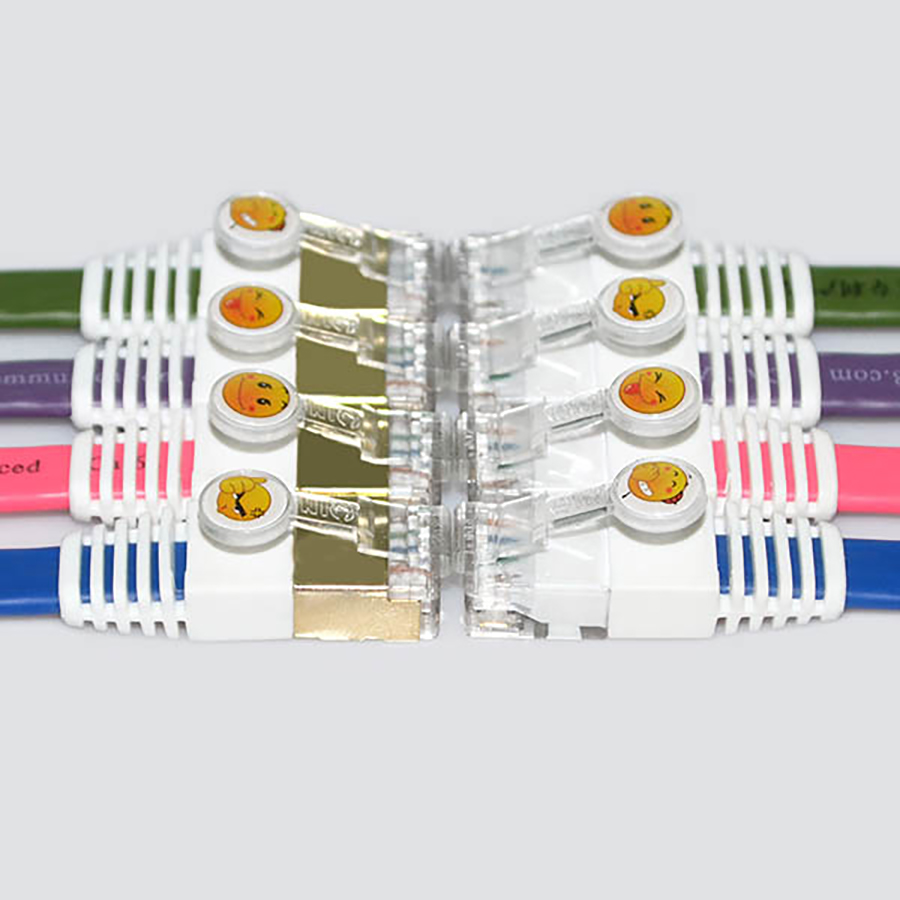

In terms of performance, industrial-grade network patch cords comply with standards such as Cat5e, Cat6, or Cat6a, supporting speeds up to 10Gbps (for Cat6a) over distances of up to 100 meters. This makes them suitable for a range of industrial applications, including connecting programmable logic controllers (PLCs), human-machine interfaces (HMIs), IP cameras (for security or process monitoring), and industrial sensors. The connectors are also ruggedized: most use RJ45 connectors with metal housings (instead of plastic) to withstand vibration and physical impact, and gold-plated contacts to ensure a secure, corrosion-resistant connection. Many connectors also feature IP (Ingress Protection) ratings—such as IP67 or IP68—meaning they are dust-tight and waterproof, making them suitable for outdoor or wet industrial environments (e.g., food processing plants with frequent washdowns).

Durability and longevity are key priorities for industrial-grade patch cords. They undergo rigorous testing to ensure they meet industrial standards, including resistance to vibration (per IEC 60068-2-6), temperature cycling (per IEC 60068-2-14), and chemical exposure (per IEC 60068-2-54). This ensures that they can operate reliably for years, even in the harshest conditions, reducing the need for frequent replacements and lowering maintenance costs. Whether used to connect machinery in a factory, monitor equipment in an oil refinery, or transmit data in a power station, the industrial-grade network patch cord delivers the ruggedness, reliability, and performance needed to keep industrial operations running smoothly.

Read recommendations:

LEG 77253 Multi-support Triple Socket Mosaic - 3 x 2P+E Automatic Terminals German Standard White

-

Network Patch Cord Cat8

Oct 23, 202592

-

Network Rack Wall Mount with Glass Door

Jan 07, 202679

-

Network Rack Wall Mount 9U

Jan 06, 202675

-

Network Cable Management Tray

Oct 30, 202573

-

Network Cable Management Under Desk

Dec 25, 202572