- Language

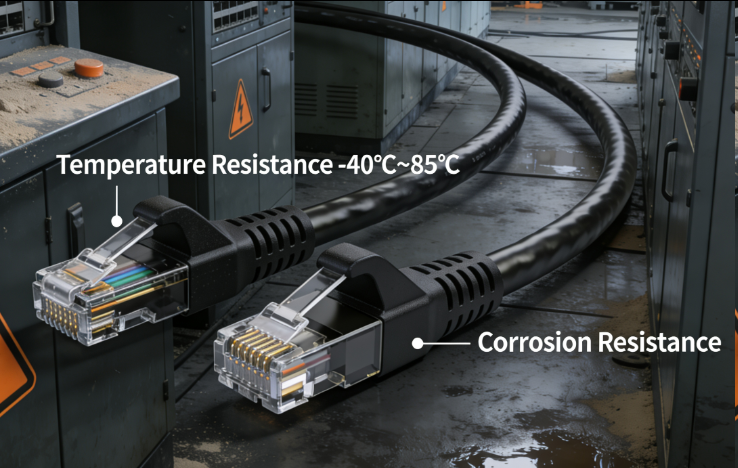

Network Patch Cord for Industrial Environment

Industrial environments, such as oil refineries, mining sites, and chemical plants, present unique challenges for network patch cords, including dust, moisture, chemical exposure, and physical impact. Network patch cords designed for these environments are specifically engineered to withstand these harsh conditions, ensuring reliable data transmission in critical applications such as process control, asset monitoring, and safety systems. Their robust construction is the key to their ability to operate in such demanding settings.

Dust and moisture resistance are achieved through the use of sealed connectors and water-resistant jacket materials. Many industrial environment patch cords feature IP67 or higher ingress protection ratings, meaning they are completely dust-tight and can withstand temporary immersion in water. For chemical resistance, the jacket materials are often made from halogen-free, flame-retardant compounds that can resist exposure to oils, solvents, and other corrosive substances commonly found in industrial settings.

Physical durability is another important aspect. These patch cords are reinforced with materials like aramid fiber (Kevlar) to resist pulling and stretching, and their connectors are designed to be impact-resistant. Some models also feature strain relief boots that prevent the cable from breaking at the connector junction. By combining these features, network patch cords for industrial environments ensure reliable performance even in the most challenging conditions, helping to maintain the integrity of industrial networks and prevent costly downtime.

Read recommendations:

LEG 77000 French Type Mosaic Energy Saving Switch 1 Way Switch 10AX (1 module) White

-

Network Patch Cord Cat8

Oct 23, 202592

-

Network Rack Wall Mount with Glass Door

Jan 07, 202679

-

Network Rack Wall Mount 9U

Jan 06, 202675

-

Network Cable Management Tray

Oct 30, 202573

-

Network Cable Management Under Desk

Dec 25, 202572