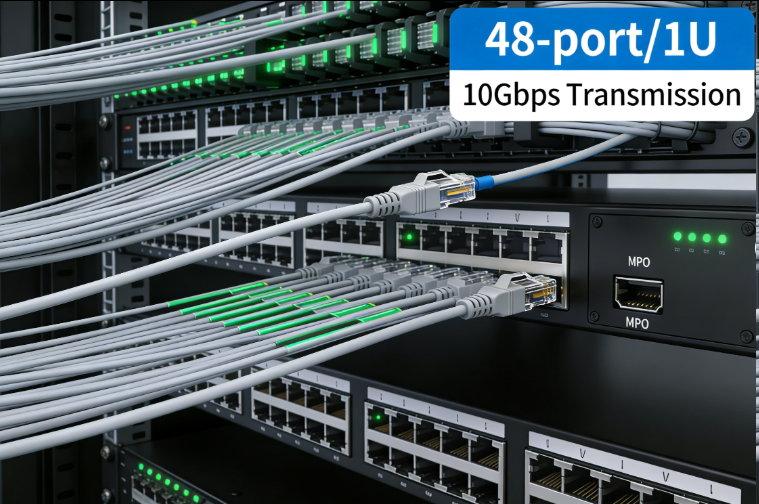

Switch stacking is a technology that connects multiple switches into a logical whole to expand network ports and improve network reliability. The 10G network patch cord for switch stacking plays a vital role in this process, as it is responsible for the high-speed data synchronization between stacked switches. The transmission speed of 10Gbps ensures that the information exchange between switches is timely and efficient, making the stacked switches operate as a single device, thereby reducin

Switch stacking is a technology that connects multiple switches into a logical whole to expand network ports and improve network reliability. The 10G network patch cord for switch stacking plays a vital role in this process, as it is responsible for the high-speed data synchronization between stacked switches. The transmission speed of 10Gbps ensures that the information exchange between switches is timely and efficient, making the stacked switches operate as a single device, thereby reducin

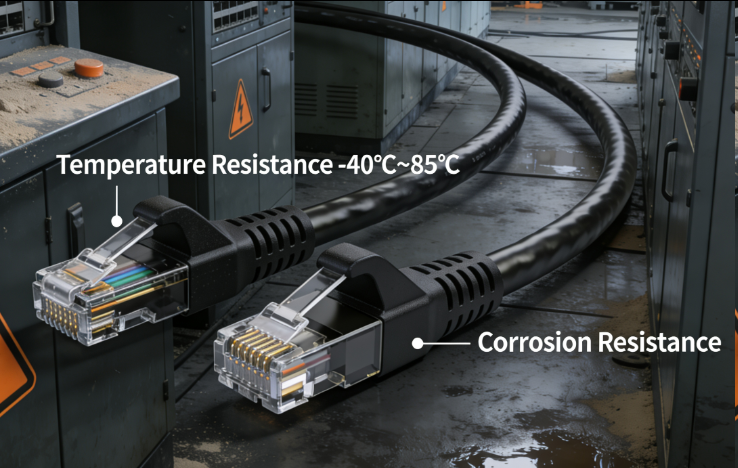

Industrial-grade 10G fiber optic network patch cord is specially developed for harsh industrial environments, with significant differences from ordinary commercial patch cords in terms of environmental adaptability and reliability. Industrial sites often face challenges such as high temperature, humidity, dust, vibration, and electromagnetic interference, and this patch cord is designed to withstand these harsh conditions. It uses a rugged cable jacket material that is waterproof, dustproof,

Industrial-grade 10G fiber optic network patch cord is specially developed for harsh industrial environments, with significant differences from ordinary commercial patch cords in terms of environmental adaptability and reliability. Industrial sites often face challenges such as high temperature, humidity, dust, vibration, and electromagnetic interference, and this patch cord is designed to withstand these harsh conditions. It uses a rugged cable jacket material that is waterproof, dustproof,

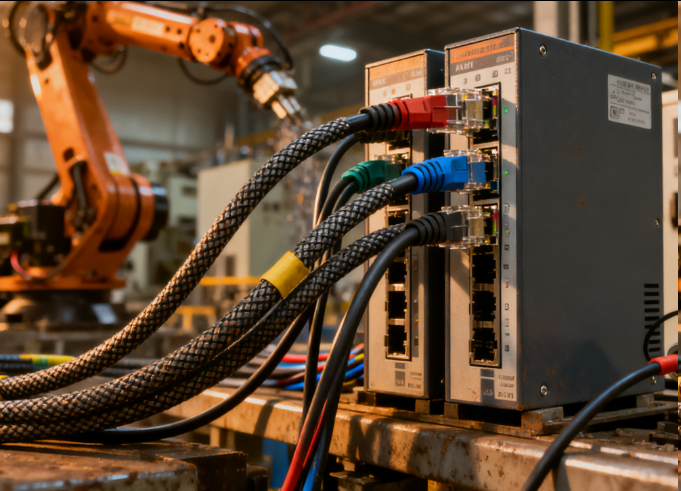

Industrial control systems (ICS) rely heavily on stable and reliable data transmission, making the industrial control network patch cord a critical component. Unlike standard patch cords used in office environments, these cords are engineered to withstand the harsh conditions of manufacturing plants, power stations, and other industrial settings. They play a vital role in connecting programmable logic controllers (PLCs), human-machine interfaces (HMIs), sensors, and actuators, ensuring seaml

Industrial control systems (ICS) rely heavily on stable and reliable data transmission, making the industrial control network patch cord a critical component. Unlike standard patch cords used in office environments, these cords are engineered to withstand the harsh conditions of manufacturing plants, power stations, and other industrial settings. They play a vital role in connecting programmable logic controllers (PLCs), human-machine interfaces (HMIs), sensors, and actuators, ensuring seaml

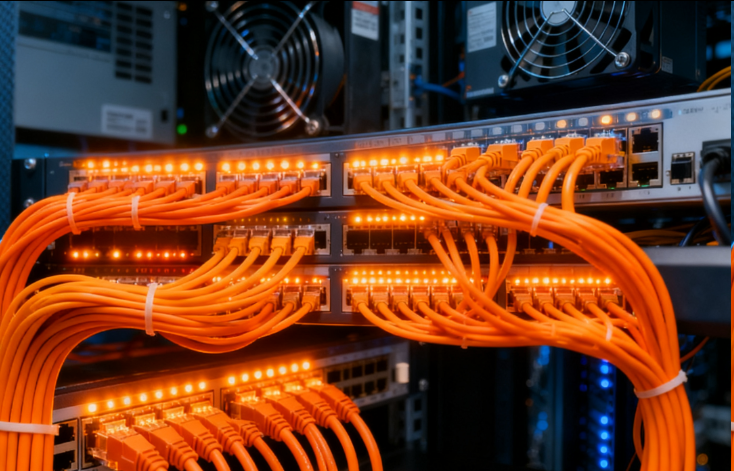

In modern data centers and network closets, where space is at a premium and port density is constantly increasing, high-density network patch cords have become an indispensable solution. These patch cords are designed to maximize the utilization of limited space while maintaining high-speed data transmission performance. Unlike traditional patch cords, which can be bulky and take up significant space between network switches and servers, high-density versions feature a more compact design th

In modern data centers and network closets, where space is at a premium and port density is constantly increasing, high-density network patch cords have become an indispensable solution. These patch cords are designed to maximize the utilization of limited space while maintaining high-speed data transmission performance. Unlike traditional patch cords, which can be bulky and take up significant space between network switches and servers, high-density versions feature a more compact design th

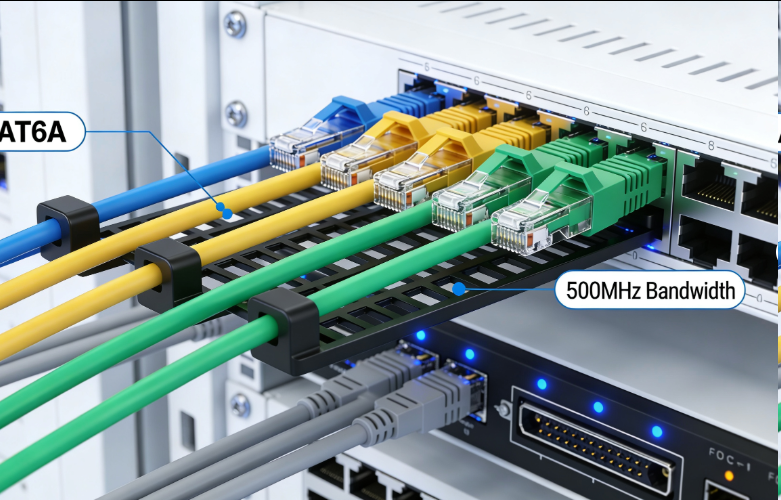

Machine room (server room) wiring is a complex and critical task that requires careful selection of network patch cords to ensure a stable, efficient, and manageable network infrastructure. The patch cords used in machine room wiring serve as the final link between network devices such as servers, switches, routers, and storage systems, and their performance directly affects the overall reliability of the network. One of the key considerations when selecting these patch cords is the cable ca

Machine room (server room) wiring is a complex and critical task that requires careful selection of network patch cords to ensure a stable, efficient, and manageable network infrastructure. The patch cords used in machine room wiring serve as the final link between network devices such as servers, switches, routers, and storage systems, and their performance directly affects the overall reliability of the network. One of the key considerations when selecting these patch cords is the cable ca

Industrial environments, such as oil refineries, mining sites, and chemical plants, present unique challenges for network patch cords, including dust, moisture, chemical exposure, and physical impact. Network patch cords designed for these environments are specifically engineered to withstand these harsh conditions, ensuring reliable data transmission in critical applications such as process control, asset monitoring, and safety systems. Their robust construction is the key to their ability

Industrial environments, such as oil refineries, mining sites, and chemical plants, present unique challenges for network patch cords, including dust, moisture, chemical exposure, and physical impact. Network patch cords designed for these environments are specifically engineered to withstand these harsh conditions, ensuring reliable data transmission in critical applications such as process control, asset monitoring, and safety systems. Their robust construction is the key to their ability

Network patch cords in computer rooms are critical for establishing reliable connections between servers, switches, and networking devices. These cables must balance performance, durability, and flexibility to meet the demands of dynamic IT environments. Typically constructed with twisted-pair copper conductors, they reduce electromagnetic interference (EMI) and crosstalk, ensuring stable data transmission. Computer room patch cords often adhere to Cat5e, Cat6, or Cat6A standards, supporting

Network patch cords in computer rooms are critical for establishing reliable connections between servers, switches, and networking devices. These cables must balance performance, durability, and flexibility to meet the demands of dynamic IT environments. Typically constructed with twisted-pair copper conductors, they reduce electromagnetic interference (EMI) and crosstalk, ensuring stable data transmission. Computer room patch cords often adhere to Cat5e, Cat6, or Cat6A standards, supporting

Industrial Ethernet network patch cords are engineered to withstand harsh environments, including extreme temperatures, vibration, and exposure to chemicals or moisture. These cables are commonly used in manufacturing plants, oil refineries, and transportation systems, where traditional networking components would fail. Constructed with ruggedized jackets made of materials like polyurethane (PUR) or thermoplastic elastomer (TPE), they resist abrasion, UV radiation, and mechanical stress. Th

Industrial Ethernet network patch cords are engineered to withstand harsh environments, including extreme temperatures, vibration, and exposure to chemicals or moisture. These cables are commonly used in manufacturing plants, oil refineries, and transportation systems, where traditional networking components would fail. Constructed with ruggedized jackets made of materials like polyurethane (PUR) or thermoplastic elastomer (TPE), they resist abrasion, UV radiation, and mechanical stress. Th

Data center network patch cords are designed for high-density, high-performance networking, where minimal latency and maximum bandwidth are essential. These cables support 10, 25, or even 40 Gigabit Ethernet (10GBase-T/25GBase-T/40GBase-T) over short distances, making them ideal for connecting servers, switches, and storage arrays. Typically classified as Cat6A, Cat7, or Cat8, they operate at frequencies up to 2000 MHz, enabling ultra-fast data transfer rates. The construction of data cente

Data center network patch cords are designed for high-density, high-performance networking, where minimal latency and maximum bandwidth are essential. These cables support 10, 25, or even 40 Gigabit Ethernet (10GBase-T/25GBase-T/40GBase-T) over short distances, making them ideal for connecting servers, switches, and storage arrays. Typically classified as Cat6A, Cat7, or Cat8, they operate at frequencies up to 2000 MHz, enabling ultra-fast data transfer rates. The construction of data cente