Fiber optic engineering

The following are the precautions that need to be paid attention to in optical fiber engineering:Pre-construction preparation stage

Optical Fiber and Material Selection: Based on engineering requirements (such as transmission distance, bandwidth, ambient temperature, etc.), select appropriate fiber types (single-mode or multi-mode). Single-mode fibers are suitable for long-distance, high-speed transmission, while multi-mode fibers are better suited for short-distance applications. Additionally, materials such as optical cables, connectors, and fusion splicing sleeves must comply with industry standards to avoid using substandard components that could lead to future failures.

Site Investigation and Design: Before construction, a thorough site survey must be conducted to determine cable routing methods (overhead, conduit, direct burial), avoid strong electromagnetic interference sources (e.g., substations, electrical equipment), high-temperature zones (e.g., near boilers), and mechanically vulnerable areas (e.g., frequently worked zones). Based on the survey results, develop a practical construction plan that clearly marks critical points (e.g., splicing joints, bends) and reserves sufficient cable length (typically 5-10 meters per end) for future maintenance.

Tools and equipment inspection: Ensure that welding machines, optical power meters, OTDR (optical time-domain reflectometer), etc. are calibrated and in normal operation, and that tools such as fiber cutting knives and stripping pliers are sharp and undamaged. Before construction, test operation of equipment is required to avoid affecting the construction progress and quality due to equipment failure.

Operational specifications during construction

1.Optical cable installation requirements: Avoid excessive bending and stretching. The bending radius must comply with specifications (typically a static bending radius of no less than 10 times the cable diameter and a dynamic bending radius of no less than 20 times). Prevent fiber loss caused by excessive bending. During installation, maintain tension within the cable's permissible range (different types require different tension levels; refer to product specifications) to avoid fiber breakage. Protect cable sheathing: Avoid friction with sharp objects during installation to prevent sheathing damage that may cause moisture or contamination. Direct-buried cables should be installed below permafrost layers with corrosion and termite-proofing treatments. Overhead cables must be securely fastened to minimize wind-induced wear. Provide clear markings: Install visible labels at cable starts, ends, bends, and reserved positions with model and length information for easy identification and maintenance.

2.Key Fiber Splicing Preparations: Clean the fiber end and V-groove of the splicer using anhydrous alcohol before welding to remove contaminants like oil and dust, ensuring the end surface is free from impurities – improper cleaning may increase splicing loss. Cutting Precision: When cutting fibers with a fiber cutter, maintain a flat, straight cut surface that meets the splicer's specified length (typically 10-16mm), and avoid touching the end surface after cutting. Splicing Parameter Settings: Configure splicer parameters (discharge duration, current, etc.) based on fiber type (single-mode or multimode). Monitor splicing progress during the process; if bubbles or poor connections occur, rewire. After completion, apply heat shrink tubing to protect the joint. When heating, ensure uniform contraction without air bubbles.

3.Connector Installation Specifications: When installing fiber optic connectors, ensure the fiber end face aligns with the connector end face to prevent gaps or protrusions. After installation, use a connector tester to verify connection quality and confirm that insertion loss meets specifications (typically ≤0.3dB for single-mode connectors and ≤0.5dB for multi-mode connectors).

Post-construction testing and acceptance

1.Performance test: attenuation test: use optical power meter to test the attenuation value of the fiber link, and ensure that the attenuation per kilometer meets the standard (single-mode fiber at 1310nm wavelength is less than or equal to 0.36dB/km, 1550nm wavelength is less than or equal to 0.22dB/km; multi-mode fiber at 850nm wavelength is less than or equal to 3.5dB/km, 1300nm wavelength is less than or equal to 1.5dB/km).

2.OTDR Testing: Utilizes OTDR to detect issues such as splice loss, connector reflections, fiber length discrepancies, and potential break points in optical fiber links. The system records test data and generates reports, which serve as critical evidence for project acceptance. Connectivity Testing: Conducts bidirectional testing using light sources and optical power meters to ensure uninterrupted signal transmission throughout the fiber link.

check and accept, check before acceptance, check upon delivery, acceptance check

During project acceptance, the construction plan and industry standards should be checked to check whether the cable laying path, quality of fusion joints and test data meet the requirements. For links that fail to pass the test, the reasons should be investigated and rectified in time until all indicators meet the standards.

Late maintenance and management

1.Regular inspection: Regularly inspect the laying path of optical cables to check whether overhead optical cables are loose, water accumulation in pipeline optical cables, and direct burial optical cables are damaged by excavation. At the same time, check whether connectors and splicing points are loose or damp, and deal with potential problems in time.

2.Fault handling: When the optical fiber link is faulty, use OTDR to locate the fault point and analyze the cause of the fault (such as poor welding, fiber breakage, connector contamination, etc.). When troubleshooting, it is necessary to clean, weld or replace parts again, and then test again to ensure that the performance meets the standard.

3.Data archiving: construction plan, test report, equipment parameters, optical cable identification and other data are sorted and archived to provide basis for later maintenance and expansion.

-

fibre-optical

Jul 22, 2025

-

Classified by control technology

Jul 22, 2025

-

Aliyun VS Baidu Cloud

Jul 19, 2025

-

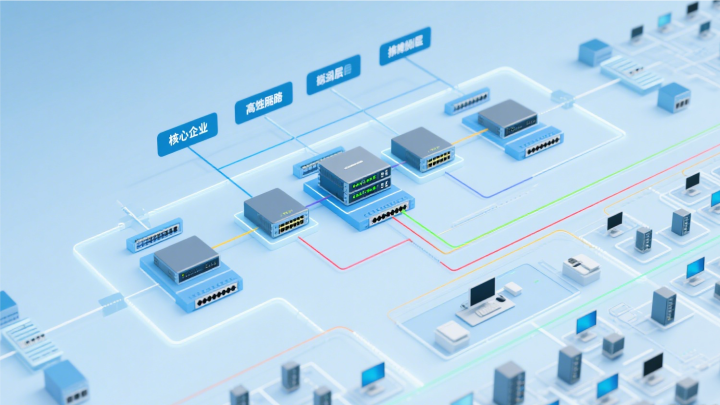

Smart factory network cabling

Jul 19, 2025

-

Full analysis of wiring test tools

Jul 19, 2025

-

Enterprise network cabling

Jul 19, 2025

-

Can you do smart control without the Internet

Jul 19, 2025

-

Principle of whole house intelligent control

Jul 18, 2025

-

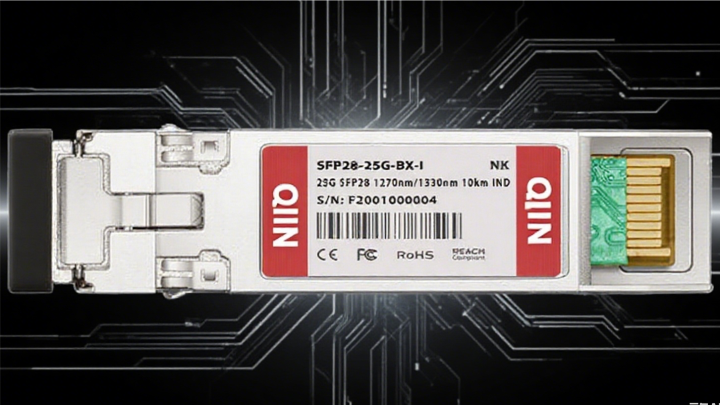

Specifications and functions of light modules

Jul 18, 2025

-

Fiber optic engineering

Jul 18, 2025

-

Common classifications and their specific types:

Jul 18, 2025

-

Parking fee system

Jul 14, 2025

-

Video face recognition big data system

Jul 14, 2025

-

Starlink is a low-orbit satellite launched by SpaceX

Jul 14, 2025

-

5G base station project

Jul 14, 2025

-

5G and Starlink overview

Jul 14, 2025

-

Internet Data Center (IDC)

Jul 11, 2025

-

Enterprise LAN solutions

Jul 10, 2025

-

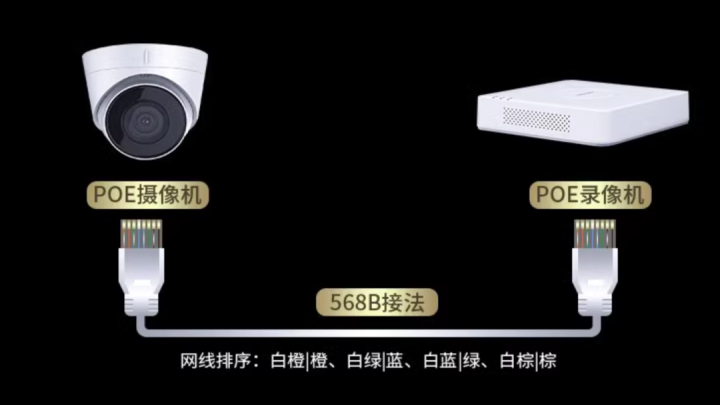

Video transmission theory

Jul 10, 2025

-

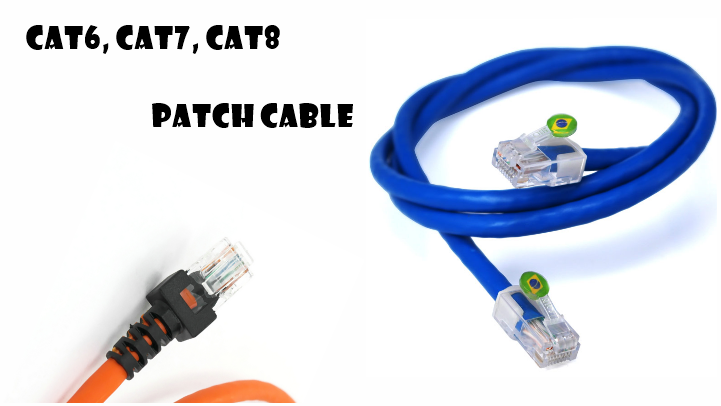

Patented technology and marked RJ45 crystal head

Jul 10, 2025

-

Advantages and disadvantages of intelligent control

Nov 30, 2024

-

Video Streaming Data Center

Nov 30, 2024

-

Computer Centre

Nov 30, 2024