Enterprise network cabling

Enterprise network cabling is the foundation of enterprise informatization construction. Its quality directly affects the stability, transmission speed, and subsequent maintenance and expansion of the network. To do a good job in network cabling, we need to take into account practicality, science and foresight. The following are some key considerations:

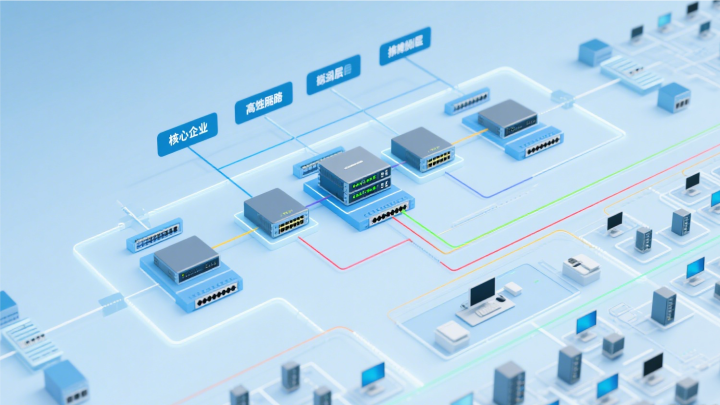

I. Preliminary planning: combining needs and future development

Define business requirements

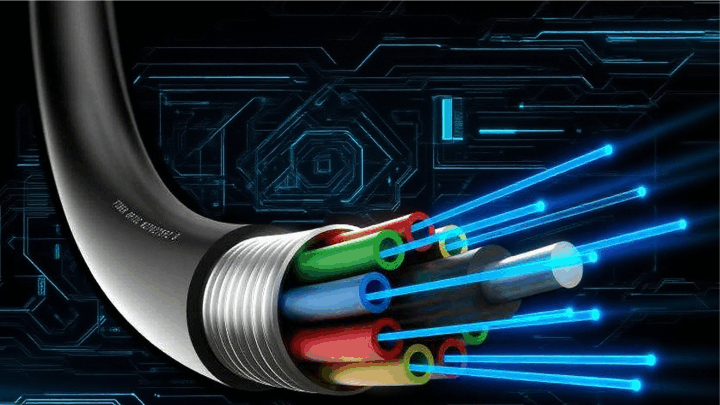

First, identify the enterprise's network requirements. This includes determining whether support for large-scale video conferencing, cloud service access, big data transmission, or specialized needs like security monitoring and IoT devices is necessary. Different requirements vary significantly in terms of bandwidth, transmission speeds (e.g., Gigabit or 10 Gigabit), and cabling types (copper or fiber). For instance, standard office environments might suffice with Category 6e copper cables, while data centers or high-bandwidth scenarios would require fiber optic solutions.

Expand the space for projection

When expanding a company's operations or installing new equipment, network infrastructure must be upgraded accordingly. During cabling planning, ensure sufficient port and cable capacity reserves—typically 20%-30% of available slots in server racks. For horizontal cabling, extend cables appropriately to prevent future rework. Additionally, adopt high-bandwidth cabling standards like Category 6a/7 cables or fiber optics to avoid performance limitations that might require replacements in the short term.

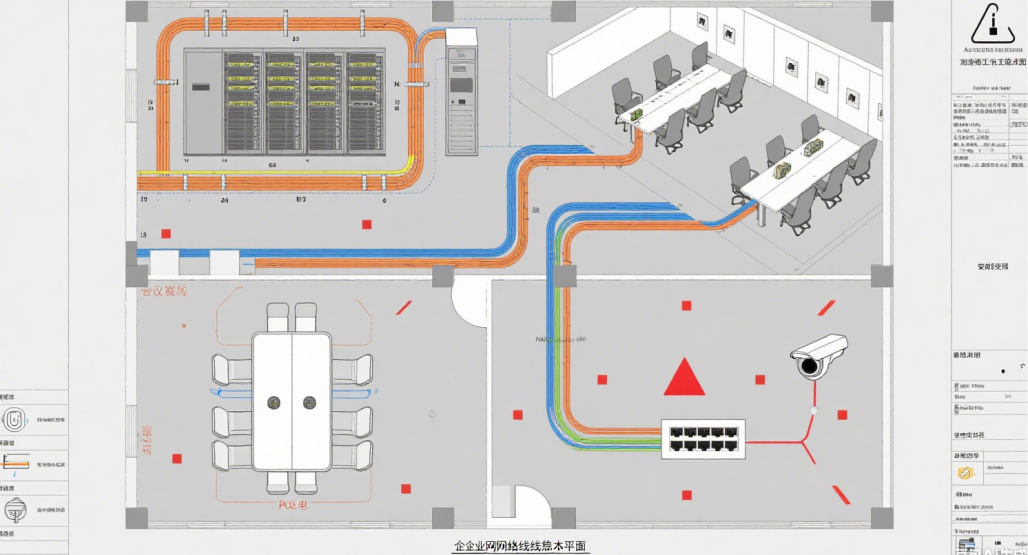

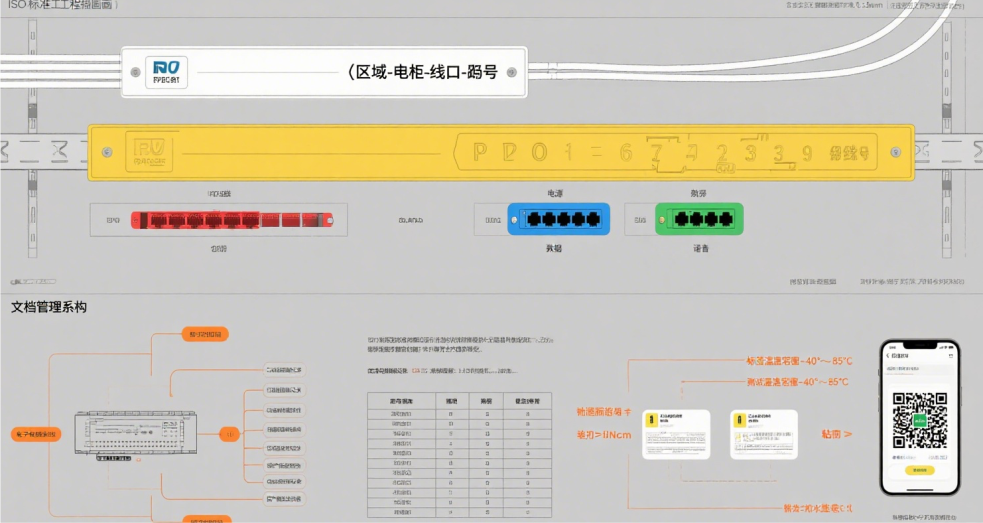

Draw detailed wiring drawings

Based on the office layout, the diagram should indicate information points (such as workstation sockets, cabinet locations, and equipment interfaces), cable routing (ceiling, underfloor, and tray paths), low-voltage shafts, and computer room locations. The drawings must clearly specify cable types, lengths, and connection methods to provide a basis for construction and later maintenance.

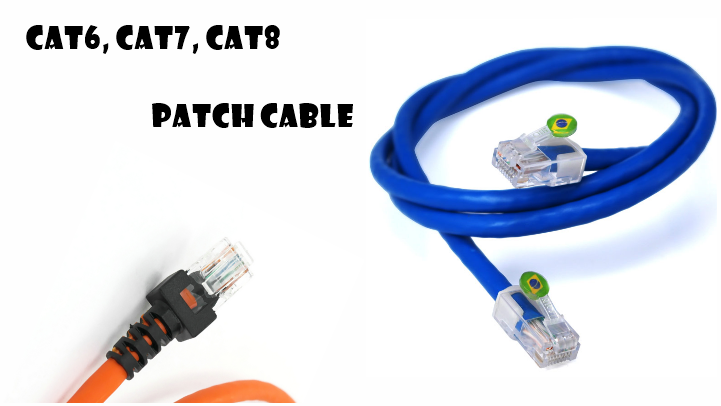

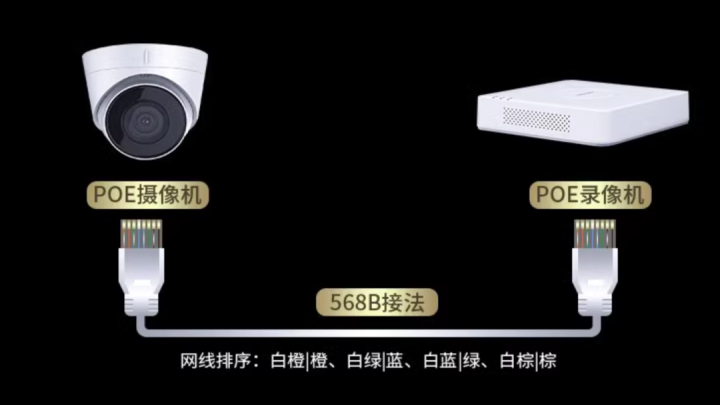

2. Material selection: pay attention to quality and adaptability

Quality control of cables and accessories

Cables are the backbone of network transmission, requiring selection of certified products from internationally recognized standards (e.g., TIA/EIA, ISO) to prevent signal attenuation and interference issues caused by substandard cables. Copper cables must be evaluated for proper wire gauge and shielding type (unshielded UTP versus shielded STP), while optical fibers should be categorized as single-mode (for long-distance transmission) or multi-mode (for short-range, high-bandwidth applications). All components including RJ45 connectors, modules, panels, and cable trays must match the cable specifications and demonstrate robust quality. —— Substandard connectors may cause frequent network disconnections due to poor contact.

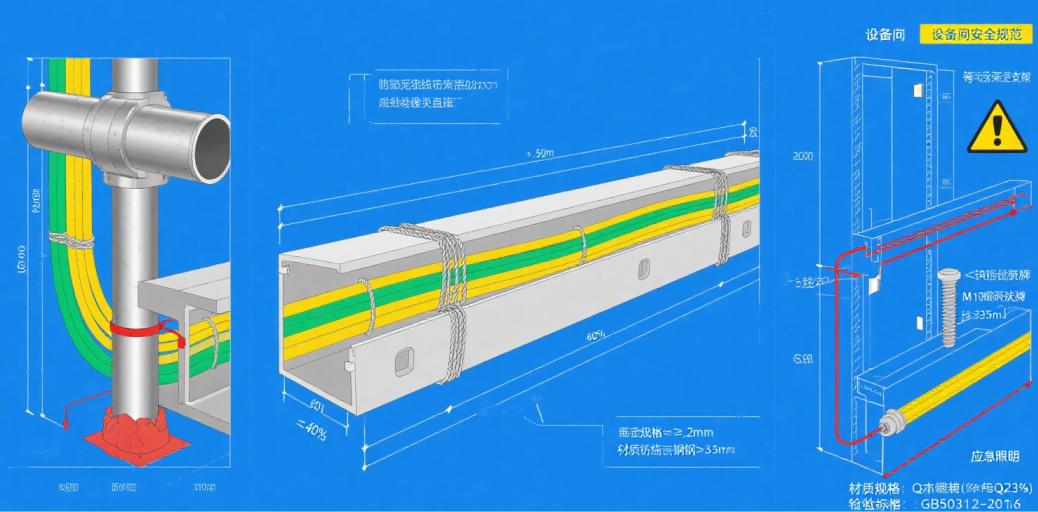

Distinguish between strong and weak electrical wiring

High-voltage power lines (power supply circuits) can generate electromagnetic interference (EMI) on low-voltage systems (network cables, telephone lines), requiring strict separation during installation. Parallel installations must maintain a minimum distance of at least 30 centimeters between both types, with perpendicular crossings being preferred. When parallel placement is unavoidable, shielded cables or metal conduits should be used for low-voltage systems to minimize interference. Additionally, low-voltage and high-voltage cable trays must be installed separately to prevent sharing of cable trenches.

3. Construction specifications: ensure the stability and safety of wiring

Cabling path and fixing method

Cables should be installed along standardized conduits such as cable trays and conduits, avoiding random pulling or exposure on floors or walls (to prevent stepping hazards and wear). When running horizontal cables, ensure proper bending radii: copper cables require a minimum of 4 times their diameter, while fiber optic cables need at least 10 times. Avoid excessive bending that may cause signal loss. Use dedicated cable ties or binding straps with moderate tension when securing cables. —— Over-tightening may compress internal components, while excessive looseness can lead to disorganization.

Cabinet and computer room wiring: clean and orderly

Cables within the cabinet should be neatly organized using cable management racks and bundling straps. Different types of cables (e.g., data cables, power cords, patch cords) must be clearly labeled and categorized. Fiber optic cables and copper cables should be stored separately to prevent fiber compression. The server room should maintain proper ventilation with controlled temperature and humidity (18-25℃°C, 40%-60% RH), while implementing dust-proof and rodent-proof measures such as installing rodent barriers and sealing cable trough gaps.

Strict testing and acceptance

After completing the wiring, each link must undergo comprehensive testing including continuity checks, signal attenuation measurements, and bandwidth verification using professional instruments like Fluke. This ensures no open circuits, short circuits, or weak signals. During final inspection, verify that cable routing, labeling, and securing comply with specifications by comparing with original blueprints. All test results should be archived for future reference.

4. Identification and documentation: Reduce maintenance costs

Full link identification is clear

Uniformly standardized labels must be affixed to all components from the information panel, cable ends to cabinet interfaces, specifying details such as link numbers, connected devices, and functions (e.g., "Workstation A-1 to Cabinet 1 Port 5"). These labels should be durable and waterproof to prevent fading over prolonged use. Fiber optic cables must also indicate specifications including type (single-mode/multi-mode) and core count.

Keep complete documentation

Organize and arrange the wiring drawings (including layout diagrams, link connection diagrams), test reports, equipment list, cable specifications and other materials, and archive them in both electronic and paper versions. These materials are important basis for troubleshooting, equipment replacement or expansion in the later stage, which can greatly reduce maintenance time.

5. Later maintenance: regular inspection and timely treatment

Daily inspection and maintenance

Conduct regular inspections to check for cable damage or looseness, dust accumulation in cabinets, and clear labeling. For fiber optic interfaces, modules, and other consumable components, perform periodic cleaning using specialized fiber optic cleaner to prevent dust interference with signal transmission. Additionally, monitor network performance changes. If frequent disconnections or speed degradation occur, promptly use diagnostic tools to identify faulty links.

Avoid changing the wiring at will

When new equipment is added or the working station is adjusted in the later stage, it is necessary to operate according to the specifications to avoid privately pulling and cutting the original cables. If modification is needed, refer to the original wiring drawings and contact professionals when necessary to prevent damage to the overall link structure.

In summary, enterprise network cabling is a "hidden project". Only through proper planning in the early stage, reliable material quality, and standardized construction can we lay a solid foundation for long-term stable network operation. Meanwhile, paying attention to signage and documentation management can effectively reduce maintenance costs later on, providing robust network support for digital operations.

-

fibre-optical

Jul 22, 2025

-

Classified by control technology

Jul 22, 2025

-

Aliyun VS Baidu Cloud

Jul 19, 2025

-

Smart factory network cabling

Jul 19, 2025

-

Full analysis of wiring test tools

Jul 19, 2025

-

Enterprise network cabling

Jul 19, 2025

-

Can you do smart control without the Internet

Jul 19, 2025

-

Principle of whole house intelligent control

Jul 18, 2025

-

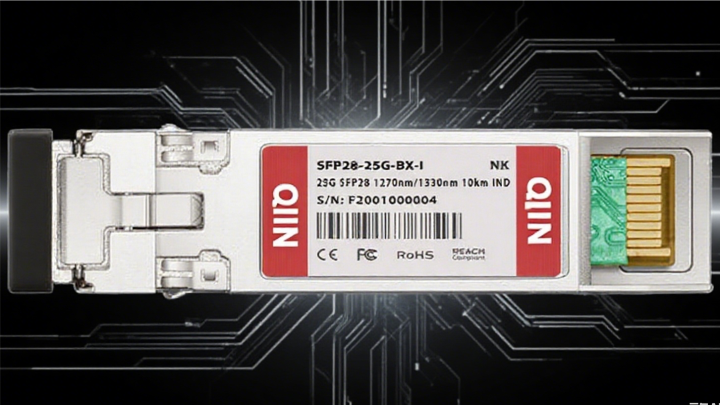

Specifications and functions of light modules

Jul 18, 2025

-

Fiber optic engineering

Jul 18, 2025

-

Common classifications and their specific types:

Jul 18, 2025

-

Parking fee system

Jul 14, 2025

-

Video face recognition big data system

Jul 14, 2025

-

Starlink is a low-orbit satellite launched by SpaceX

Jul 14, 2025

-

5G base station project

Jul 14, 2025

-

5G and Starlink overview

Jul 14, 2025

-

Internet Data Center (IDC)

Jul 11, 2025

-

Enterprise LAN solutions

Jul 10, 2025

-

Video transmission theory

Jul 10, 2025

-

Patented technology and marked RJ45 crystal head

Jul 10, 2025

-

Advantages and disadvantages of intelligent control

Nov 30, 2024

-

Video Streaming Data Center

Nov 30, 2024

-

Computer Centre

Nov 30, 2024