Click to open expanded view

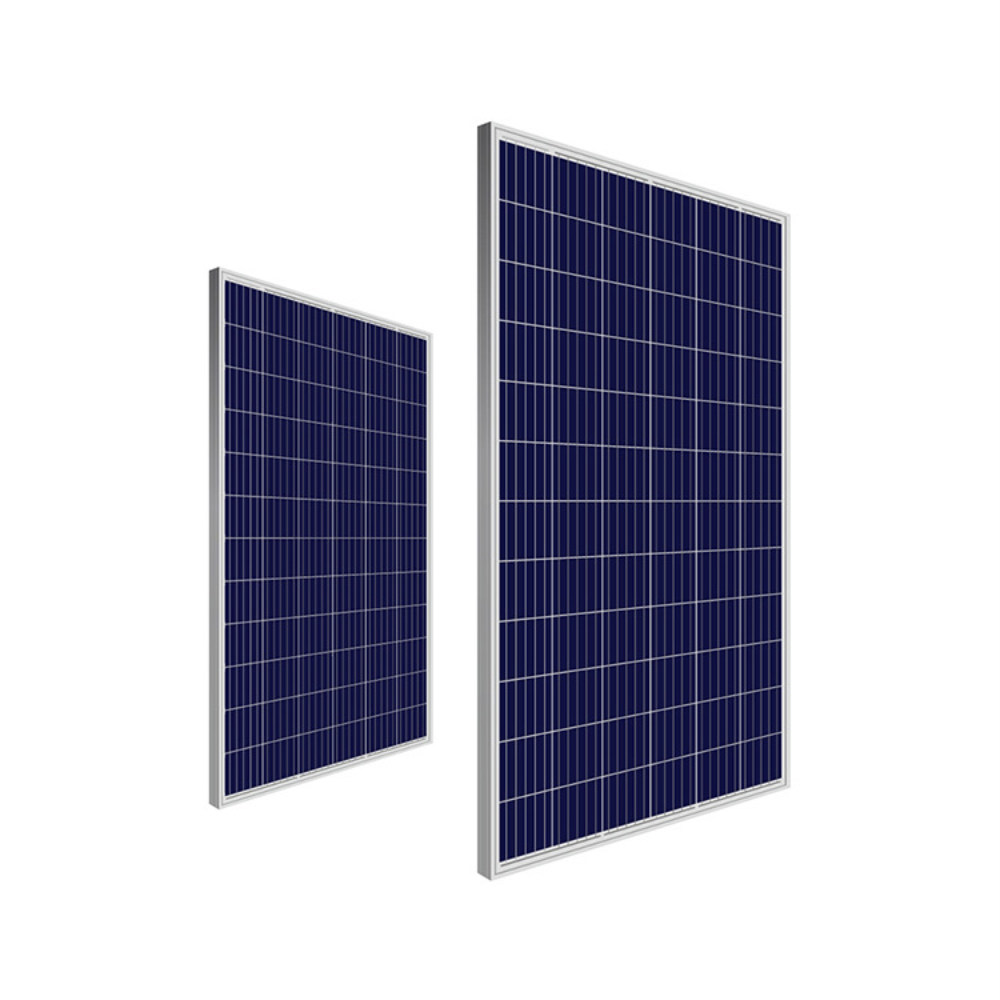

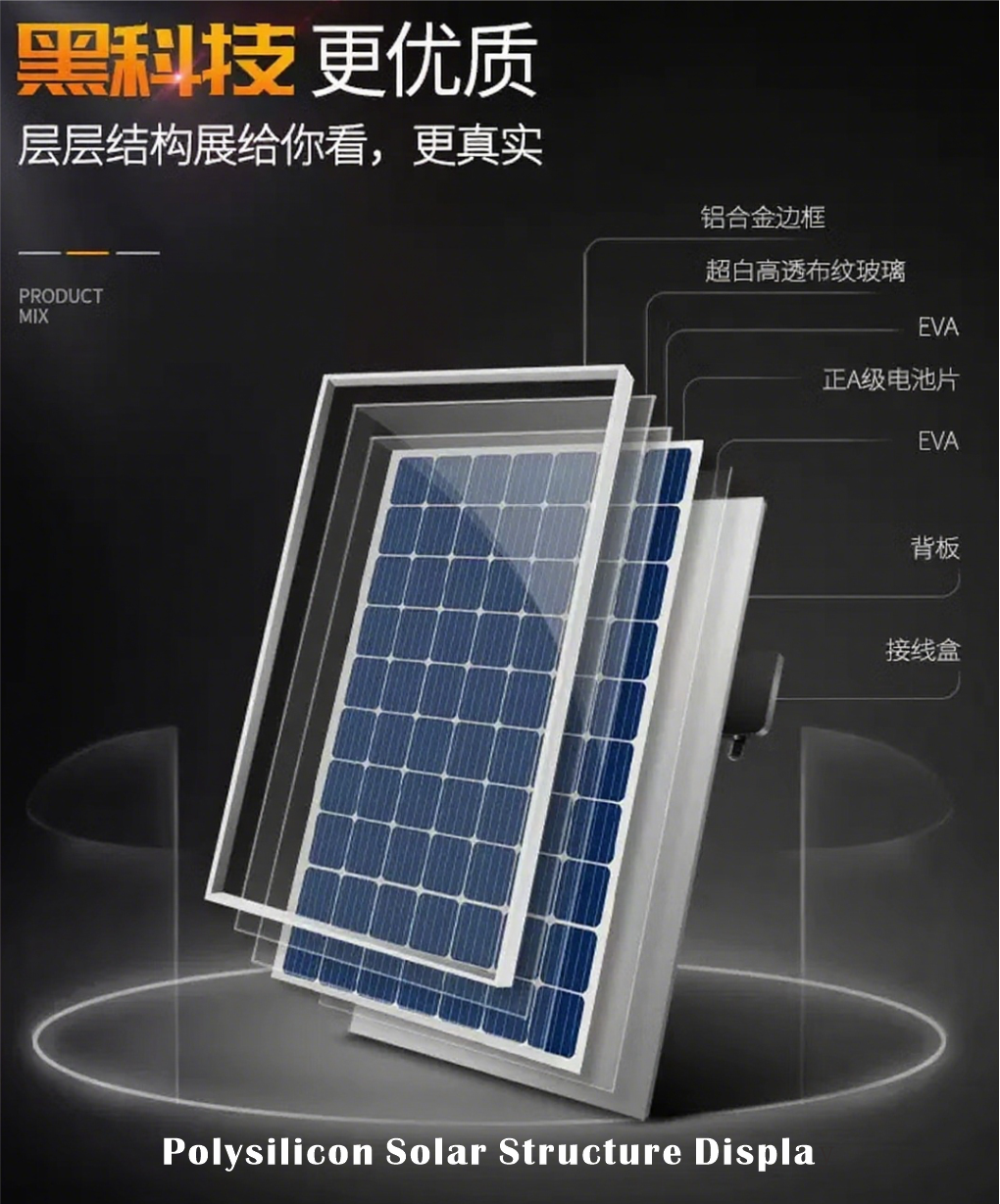

Polycrystalline silicon solar panel 350W solar panel

350W solar panel

Place of Origin Shenzhen

Brand QIN

Model 350W Solar Panel

Type Polycrystalline Module

Operating Voltage 24 (V)

Open Circuit Voltage 24 (V)

Short Circuit Current 10A (A)

Product Certification CE

The core of a polycrystalline silicon solar cell is the polycrystalline silicon wafer, which is composed of multiple single-crystal silicon grains oriented in different directions, with grain boundaries between them. This structure stems from the production process — molten silicon is poured into a mold and cooled to crystallize using the casting method, eliminating the need for the complex crystal pulling process required for monocrystalline silicon. As a result, silicon material utilization is higher, and raw material waste is reduced. The presence of grain boundaries can impede the transport of charge carriers, which is the key structural difference between polycrystalline silicon solar cells and monocrystalline silicon solar cells.

The photovoltaic conversion efficiency of polycrystalline silicon solar cells typically ranges between 15% and 20%, slightly lower than that of monocrystalline silicon cells (generally 18% to 25%). This difference primarily stems from the combined effect of grain boundaries on photo-generated carriers, which reduces carrier collection efficiency. However, their spectral response range is similar to that of monocrystalline silicon, enabling them to effectively absorb sunlight from the visible to near-infrared wavelength range. Under conventional lighting conditions, they exhibit stable power generation capabilities. Additionally, polycrystalline silicon cells are relatively less sensitive to changes in light angle, resulting in smaller fluctuations in power output under scattered light or cloudy conditions.

Polycrystalline silicon solar cells exhibit good temperature tolerance. When the operating temperature rises, the decrease in open-circuit voltage is smaller than that of monocrystalline silicon cells, so in high-temperature environments (such as midday in summer), the actual power generation decline is relatively mild. However, over the long term, due to environmental factors such as ultraviolet radiation and humidity, their power output gradually declines, with an annual average degradation rate of approximately 0.5%–1%. Their service life typically reaches 25–30 years, comparable to that of monocrystalline silicon cells.

Cost and economic efficiency are significant advantages of polycrystalline silicon solar technology. Due to its simpler production process (the casting method is less costly than the Czochralski method used for monocrystalline silicon), the manufacturing cost of polycrystalline silicon wafers is only 70%-80% of that of monocrystalline silicon wafers, making polycrystalline silicon solar modules more cost-competitive, particularly suitable for cost-sensitive applications such as large-scale ground-mounted photovoltaic power plants. Additionally, its high material utilization rate further reduces the raw material cost per unit of power.

In practical applications, polycrystalline silicon solar cells are widely used in large-scale photovoltaic power stations and commercial and industrial distributed power generation systems due to their cost-effectiveness. Although their conversion efficiency is slightly lower, the difference in power generation can be compensated for by increasing the number of components at the same cost, resulting in better overall economic performance.

However, polycrystalline silicon solar cells also have certain limitations. In addition to their lower conversion efficiency compared to monocrystalline silicon, their power generation performance in low-light environments is also slightly inferior.