- Language

Certified Quality

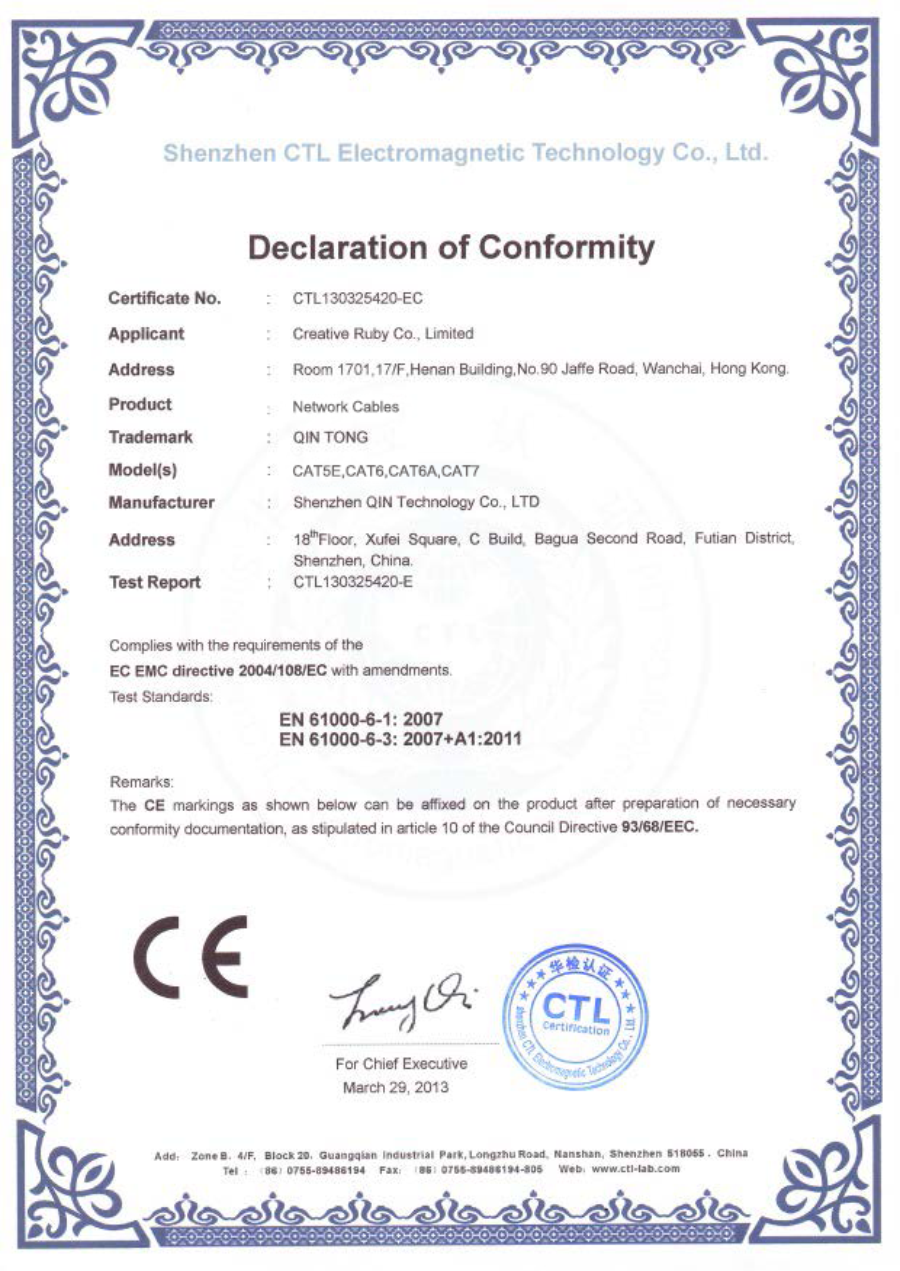

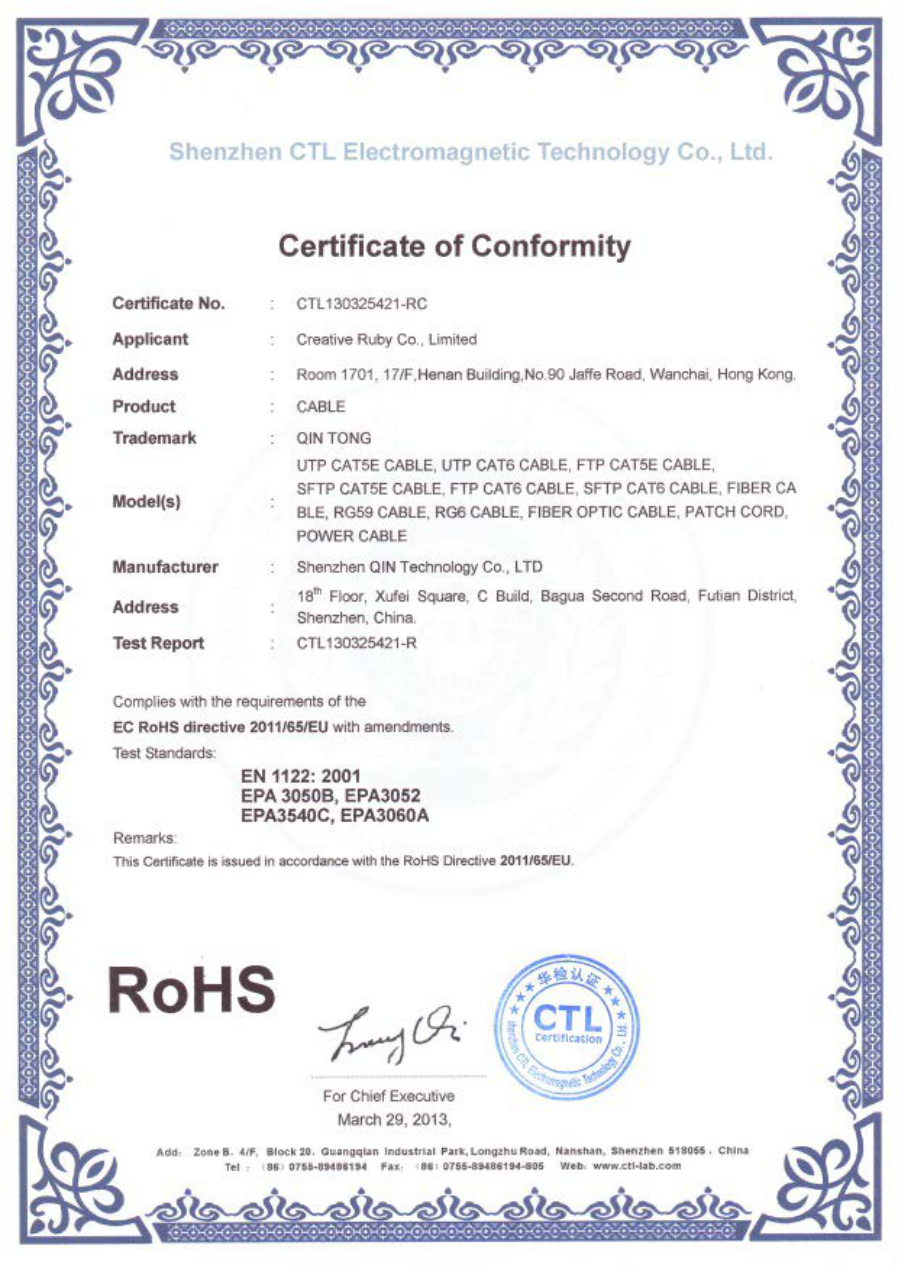

Dual endorsement of international certification bodies and standards

1.Qin Shen knows that international certification is the "passport" for products to enter the global market, so he actively connects with top certification agencies around the world and conducts full process quality control based on international universal standards

Authoritative agency cooperation: Establishing long-term cooperation with international certification agencies such as SGS (Swiss General Notary), T Ü V Rheinland (German Technical Supervision Association), UL (Underwriters Laboratories), Intertek (UK Intertek Group), etc. to conduct comprehensive testing and certification of products. These institutions conduct full chain audits based on international standards such as ISO, IEC, ASTM, etc., from raw materials, production processes to finished product performance, ensuring that certification results have global credibility.

Core international standards cover:

Accurately match international standards based on product types, such as:

Electronic and electrical products comply with IEC 60950 (Information Technology Equipment Safety) and IEC 61000 (Electromagnetic Compatibility);

Mechanical components comply with ISO 9001 (Quality Management System) and ISO 14001 (Environmental Management System);

Communication products meet the transmission performance standards of ITU-T (International Telecommunication Union) and the network protocol standards of IEEE (Institute of Electrical and Electronics Engineers).

Each type of product has passed the corresponding standard certification and obtained international market access qualifications.

2. Meet customers' customized certification capabilities that exceed international standards

Some industry clients, such as aerospace, medical equipment, and high-end industrial sectors, may demand quality requirements higher than internationally recognized standards due to the unique application scenarios. Qin achieves precise response to such demands through the model of "standard disassembly+technical breakthrough+special certification":

Standard interpretation and conversion: After receiving the customer's request for exceeding the standard, the technical team will first break it down into quantifiable indicators (such as a medical equipment customer's requirement to increase the product's temperature resistance range from -20 ℃~60 ℃ to -40 ℃~80 ℃ according to international standards, and the failure rate must be less than 0.1%/1000 hours), and confirm the testing method and judgment basis with the customer.

Technical solution adaptation: Conduct specialized research and development for exceeding standard indicators, such as improving product performance by replacing high-temperature resistant raw materials, optimizing structural design, upgrading production processes, etc. At the same time, simulate extreme environments in internal laboratories for pre testing to ensure that samples meet customer requirements.

Third party special certification: Invite the international certification agency designated by the customer (or an authoritative organization recognized by both parties) to conduct ultra standard testing on the product and issue a special certification report. For example, a connector customized for an aviation customer not only passed the internationally recognized ISO 13485 (Medical Equipment Quality Management System) certification, but also additionally passed the NASA (National Aeronautics and Space Administration) space environment tolerance test requested by the customer, proving that the product can work stably in extreme space environments.

3. Full process quality control with certification as the starting point

Qin integrates international certification standards and customized customer requirements into every aspect of the product lifecycle, forming a closed loop of "prevention control improvement":

R&D stage: Implant international standards and customer specific requirements in the early design stage, predict potential quality risks through DFMEA (Design Failure Mode and Effects Analysis), and avoid rework caused by non-compliance with standards in the later stage;

Production stage: Develop work instructions based on certification standards, use automated equipment to reduce human errors in key processes, and monitor production parameters in real-time through SPC (Statistical Process Control) to ensure product consistency;

After sales stage: Collect customer feedback and product operation data, compare the differences between certification standards and actual usage scenarios, continuously optimize product design and production processes, and upgrade quality control from "meeting standards" to "exceeding expectations".

Whether following internationally recognized standards for certification or responding to customer demands for exceeding standards, Qin always puts "compliance" and "reliability" at the core. Through third-party endorsement by international certification bodies and its own technical strength, it provides reliable high-quality products to global customers.