- Language

The Importance of Network Cabling for Smart Factories

In the architecture of a smart factory, network cabling is not simply a matter of connecting cables, but rather a “neural network” that supports the intelligent operation of the entire factory. Its importance is reflected in multiple dimensions and directly affects the factory's production efficiency, management precision, and development potential.

1. Ensuring real-time and reliable data transmission to lay a solid foundation for intelligent manufacturing.

The core of a smart factory lies in “data-driven production.” From the collection of real-time parameters such as temperature and pressure by sensors in the workshop, to the transmission of motion commands for industrial robots, to the interaction between production data and ERP systems, every link relies on stable network transmission. High-quality network cabling ensures data is transmitted within milliseconds or even microseconds, preventing production disruptions caused by delays. For example, if there is a delay in the transmission of CNC machine tool processing parameters, it may result in part accuracy deviations; if AGV navigation data is interrupted, it may directly cause logistics stagnation. Additionally, the cabling system's interference resistance (such as shielding design and reasonable cable spacing) reduces the impact of electromagnetic interference on data, lowers packet loss rates, and ensures the integrity of production data. Complete data is a prerequisite for factories to conduct quality traceability and process optimization.

2. Support equipment collaboration and process automation to improve production efficiency.

A typical feature of smart factories is equipment interconnection and process automation, all of which are linked by network cabling. Through a structured cabling system, equipment such as machine tools, robots, and conveyor belts on the production line can communicate seamlessly, forming a “smart unit” that works collaboratively. For example, when a piece of equipment detects a fault, it can immediately synchronize the information to the central control system via the network. The system then dispatches a backup device to take over and notifies maintenance personnel to bring tools to the site. The entire process requires no human intervention, significantly reducing downtime. Additionally, the IoT platform connected to the cabling system enables automated scheduling of production processes: raw material inventory data triggers the production planning system, which automatically generates work orders and assigns them to the corresponding production lines. Production line progress data is fed back in real-time to the warehouse system, triggering replenishment instructions... This end-to-end automated collaboration relies on the stable connectivity provided by the cabling system. If the cabling system becomes a bottleneck, the collaborative chain may break, leading to a significant decline in production efficiency.

3. Empowering data integration and intelligent decision-making to drive factory digital transformation.

The ultimate goal of a smart factory is to achieve “smart manufacturing” through data integration, and the cabling system serves as the “blood vessels” for data aggregation. Real-time production data, equipment operation data, energy consumption data, and other information from the workshop are transmitted via the cabling system to the data center. After analysis by AI algorithms, this data can generate decision-support information such as equipment maintenance alerts, production process optimization recommendations, and energy consumption control plans. For example, by analyzing vibration data from multiple devices, the system can predict fault risks in advance to avoid sudden shutdowns. By comparing production parameters and quality data across different batches of products, process parameters can be optimized to improve合格率. If the cabling system cannot support high-speed transmission of massive amounts of data or has data transmission bottlenecks, the timeliness and integrity of data integration will be significantly compromised, rendering intelligent decision-making ineffective. Additionally, the scalability of the cabling system (such as reserved fiber optic interfaces and support for 10-gigabit Ethernet) can adapt to the needs of factory digital upgrades, providing the network foundation for introducing new technologies like AI visual inspection and digital twins.

4. Ensure production safety and system stability, and reduce operational risks.

The safety of smart factories not only includes equipment and personnel safety, but also covers network security and production system stability. Reasonable wiring design (such as physically isolating the production network from the office network and using shielded cables to resist electromagnetic interference) can reduce the risk of network attacks and signal interference, and avoid production accidents caused by network paralysis. For example, if the cabling between the production network and external networks is not properly isolated, it may be vulnerable to malware attacks, leading to equipment malfunction; if power cables and sensor cables are laid parallel without shielding measures, electromagnetic interference may cause sensor false alarms, resulting in production line shutdowns. Additionally, redundant design in the cabling system (such as dual-line backup at critical nodes) can automatically switch to the backup line in case of a single-line failure, ensuring uninterrupted production. This is particularly beneficial for continuous production facilities, as it significantly reduces economic losses caused by network failures.

-

Aliyun VS Baidu Cloud

Jul 19, 20254760

-

The Importance of Network Cabling for Smart Factories

Jul 19, 20254742

-

Full analysis of wiring test tools

Jul 19, 20254737

-

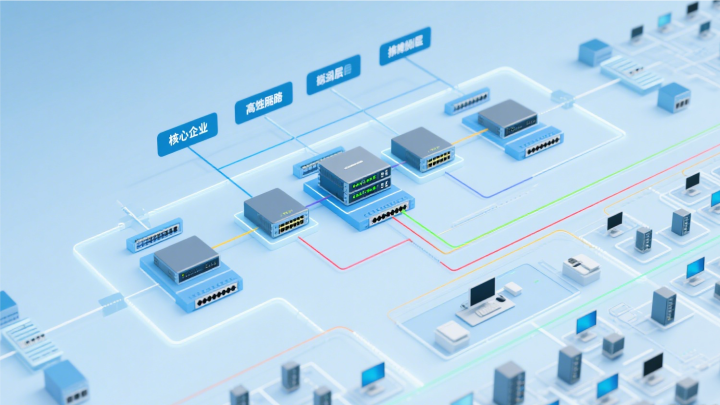

Enterprise network cabling

Jul 19, 20252432

-

Can you do smart control without the Internet

Jul 19, 20253496

-

Principle of whole house intelligent control

Jul 18, 20253510

-

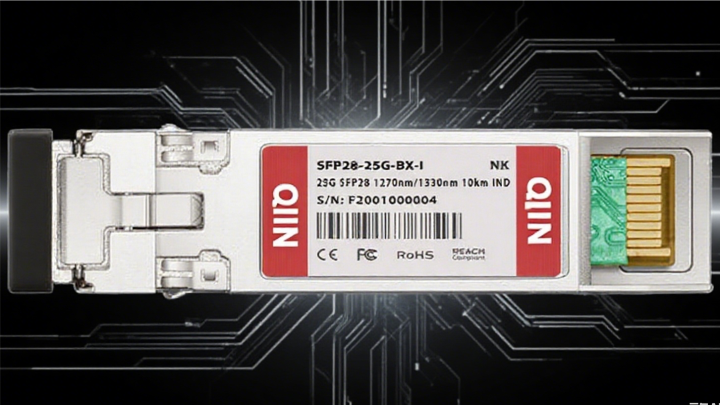

Specifications and functions of light modules

Jul 18, 20254631

-

Fiber optic engineering

Jul 18, 20252436

-

Common classifications and their specific types:

Jul 18, 2025186

-

Parking fee system

Jul 14, 2025338

-

Video face recognition big data system

Jul 14, 20253414

-

Starlink is a low-orbit satellite launched by SpaceX

Jul 14, 20254631

-

5G base station project

Jul 14, 20253727

-

5G and Starlink overview

Jul 14, 20254750

-

Enterprise LAN security access control system project

Jul 14, 20253517

-

Internet data centers are the nerve center of the digital economy

Jul 14, 20252431

-

Internet Data Center (IDC)

Jul 11, 20254609

-

Enterprise LAN solutions

Jul 10, 20253342

-

Video transmission theory

Jul 10, 20258892

-

Patented technology and marked RJ45 crystal head

Jul 10, 202533733

-

The relationship between network and intelligent control

Nov 30, 20245264

-

Advantages and disadvantages of intelligent control

Nov 30, 20244606

-

Video Streaming Data Center

Nov 30, 20244653

-

Computer Centre

Nov 30, 20243378